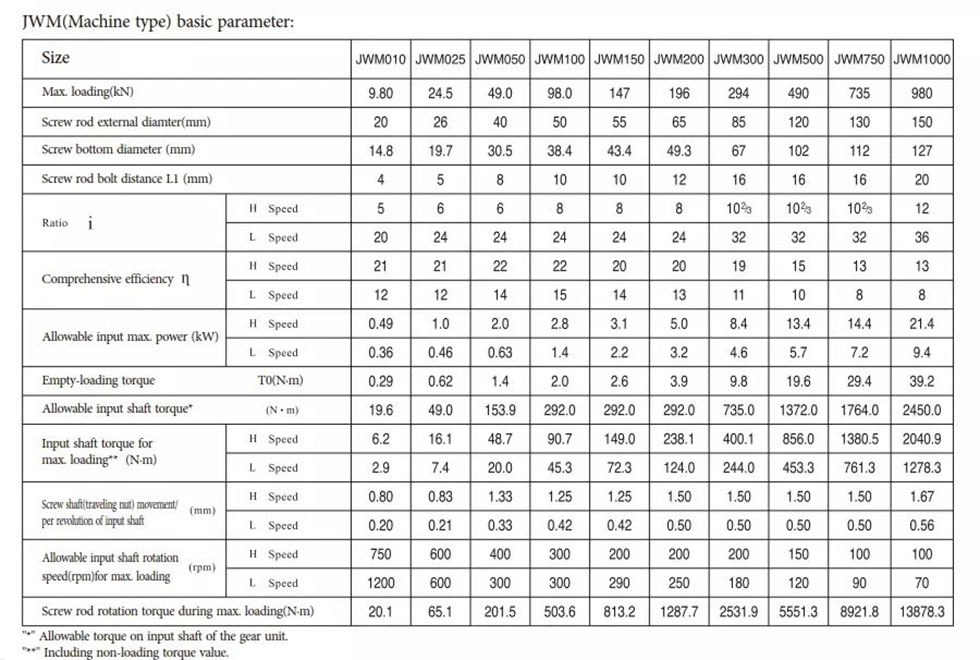

Our JWM Series Worm Screw Jack(also named acme screw jack) is suitable for low speed and low frequency.JWM Series Worm Screw Jack is a basis jack-up part, accomplish the functionssuch as lifting, drop, push and inverting through worm gear drives screw.Compact configuration, small size, lightweight, convenient installation,flexible operation, high reliability and stability, also has a long service life and more connection form etc.

The JWM Series Worm Screw Jack can be driven by different motors: electrical, with either alternating or direct current, as well as hydraulic or pneumatic motors. Also they can be driven manually or with any other type of transmission.

JWM Series Worm Screw Jack can be used singly or in combination, and can accurately control and adjust the lifting or advancing and height according to a certain program, which can be directly driven by electric motor or other power, or manually. It has different structure type and assembly type, and the lifting height can be customized according to the user's requirements.

1.The product features a proprietary modular architecture with patented biomimetic surface technology, ensuring unique design integrity and intellectual property protection.

2.Precision manufacturing is achieved through the utilization of German-engineered worm hobs for worm wheel processing, guaranteeing superior gear quality and performance.

3.Engineered for optimal performance, the system demonstrates exceptionally low friction coefficients, extended service durability, and enhanced energy efficiency.

4.Offering exceptional versatility, the drive system supports multiple power input configurations, including electric motors, alternative power sources, and manual operation capability.

5.The product line provides comprehensive output configuration options, delivering flexible solutions for diverse application requirements across various industries.

Hoist and transport

Building and construction

Forest and paper

Metal processing

Agriculture and food

| Housing material | Cast iron/Ductile iron |

| Housing hardness | HBS190-240 |

| Gear material | 20CrMnTi alloy steel |

| Surface hardness of gears | HRC58°~62 ° |

| Gear core hardness | HRC33~40 |

| Input / Output shaft material | 42CrMo alloy steel |

| Input / Output shaft hardness | HRC25~30 |

| Machining precision of gears | Accurate grinding, 6~5 Grade |

| Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

| Heat treatment | Tempering, cementiting, quenching, etc. |

| Efficiency | 94%~96% (depends on the transmission stage) |

| Noise (MAX) | 60~68dB |

| Temp. Rise (MAX) | 40°C |

| Temp. Rise (Oil)(MAX) | 50°C |

| Vibration | ≤20µm |

| Backlash | ≤20Arcmin |

| Brand of bearings | China top brand bearing, HRB/LYC/ZWZ/C&U. Or other brands requested, SKF, FAG, INA, NSK. |

| Brand of oil seal | NAK --- Taiwan or other brands requested |

Address

Pingyang Economic Developing Zone,Wenzhou City,Zhejiang Province,China

Tel

Phone no.: